Bogor City uses domestic waste to generate clean energy for cooking

November 12, 2021

Colombia advances in the integration of climate change into National Urban Policies, with technical assistance from Urban-LEDS and UN-Habitat’s guiding frameworks

November 17, 2021Bogor City puts up community-scale waste management pilot project using hydro-pyrolysis technology

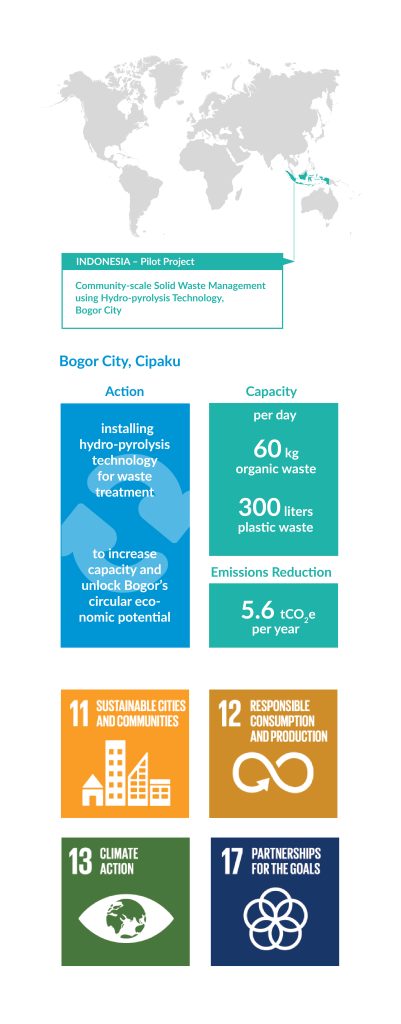

The Urban-LEDS II Project supported Bogor City in managing municipal solid waste at the community level through hydro-pyrolysis technology. This technology aims to reduce greenhouse gases—particularly methane gas—generated by the waste sector, enhancing the involvement of the beneficiary community in managing Municipal Solid Waste (MSW), and introducing hydro-pyrolysis products from waste streams in order to cultivate the city’s circular economy.

Given the context, ICLEI SEAS announced a call for a proposal to the Indonesian Urban-LEDS II cities for awarding grants up to EUR 20,000 in implementing a pilot project titled “Community-scale Solid Waste Management using Hydro-pyrolysis Technology”. As it turned out, Bogor City was chosen to support the implementation of the pilot project.

Municipal Solid Waste (MSW): Part of Problem, Therefore of the Solution

According to 2020 data from the National Waste Management Information System (locally named Sistem Informasi Pengelolahan Sampah Nasional or SIPSN), MSW in Indonesia is dominated by mixed organic waste (50%), with plastics (17%) being another major component. Other MSW includes paper, metal, and rubber, among others.

A typical waste treatment facility in Indonesia usually processes the waste through manual sorting and composting. This method amounts to approximately 70.1% of the waste being processed. However, the composting process takes a long time and becomes an issue due to its large area requirements. Common timeframes in commercial composting operations range from 1 to 4 months (Lide Chen, 2011). Thus, the available area needed for composting is up to 120 times the daily production of organic waste.

By using thermal technologies, the amount of processed waste could be increased and the required area for waste treatment could be reduced significantly. Hydro-pyrolysis is one such suitable thermal technology for mixed MSW processing.

In order to effectively unlock Bogor’s circular economy potential and gauge the applicability and sustainability of hydro-pyrolysis technology, the ICLEI Southeast Asia Secretariat (SEAS) performed a preliminary assessment including social preparation and acceptability, technical viability, and market strategy.

The assessment results showed that not only is MSW management feasible through hydro-pyrolysis, but the process can also potentially present further commercial value for the city.

Hydro-pyrolysis: One of the Sustainable Ways to Promote Circular Economy from Waste

Hydro-pyrolysis is the combination of hydrothermal and pyrolysis processes.

Hydrothermal[1] technology involves a thermo-chemical process that uses water as a medium for the reaction. Based on several studies, it is applicable in processing various types of feedstocks, including MSW, diapers and biomass. Hydrothermal technology entails high temperatures and pressures that can convert feedstock into solid product which has better characteristics both as solid fuel and compost. Moreover, it is also proven to produce liquid fertilizer that has similar nitrogen, phosphor, and potassium (locally named NPK) content to commercially-available fertilizers.

Pyrolysis1 works by decomposing the feedstock with heat in the absence of oxygen. Pyrolysis technology has great potential to process plastic waste and produce liquid oil that can be utilized as a fossil fuel substitute. Moreover, the liquid oil product can also be used as a fuel source to operate hydrothermal technology. This can be an alternative solution to the business-as-usual scenario of burning plastic wastes that is a major source of air pollution. Moreover, burning plastic wastes can also release carcinogenic substances and cause respiratory ailments.

[1] PT Sakura Integra Semesta. Preliminary Report: Urban-LEDS II: Community-Scale Solid Waste Management Using Hydro-Pyrolysis Technology in Bogor City, Indonesia, (2021). p02.

Bogor City plans to expand the pilot project to further pursue a sustainable waste management

Led by the ICLEI Indonesia Office, the pilot project commenced last July 2021, with testing and commissioning successfully completed at the end of September 2021. A contracted service provider assisted in the processes of detailed engineering design, procurement of unit components and other materials, fabrication, set-up and installation, testing, commissioning, monitoring, and maintenance.

The hydrothermal technology can process 20 kg of organic waste and pyrolysis can manage 100 L of plastic waste per batch. The hydro-pyrolysis technology can run up to three batches per day. By using Clean Development Mechanism (CDM) tools No. 3, 4, 5, and 12, it is estimated that GHG emissions reduction amount to 5,604.25 kg CO2e/year or 5.6 tCO2e/year by treating 60 kg of organic waste per day and 300 L of plastic waste per day.

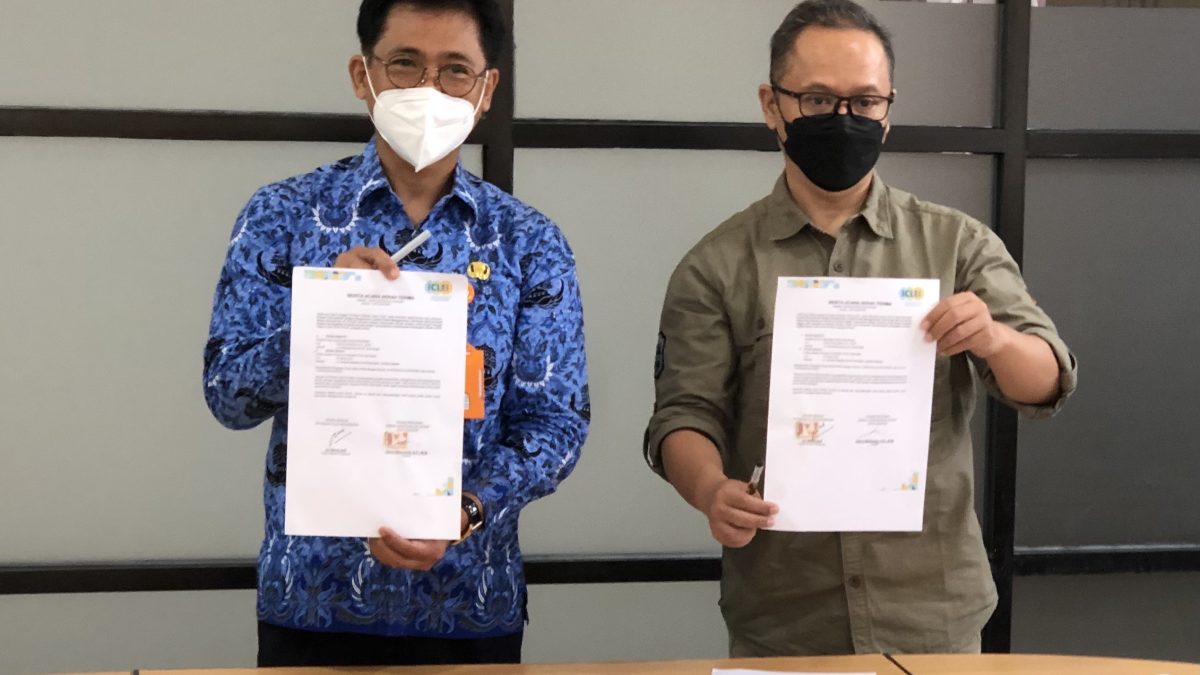

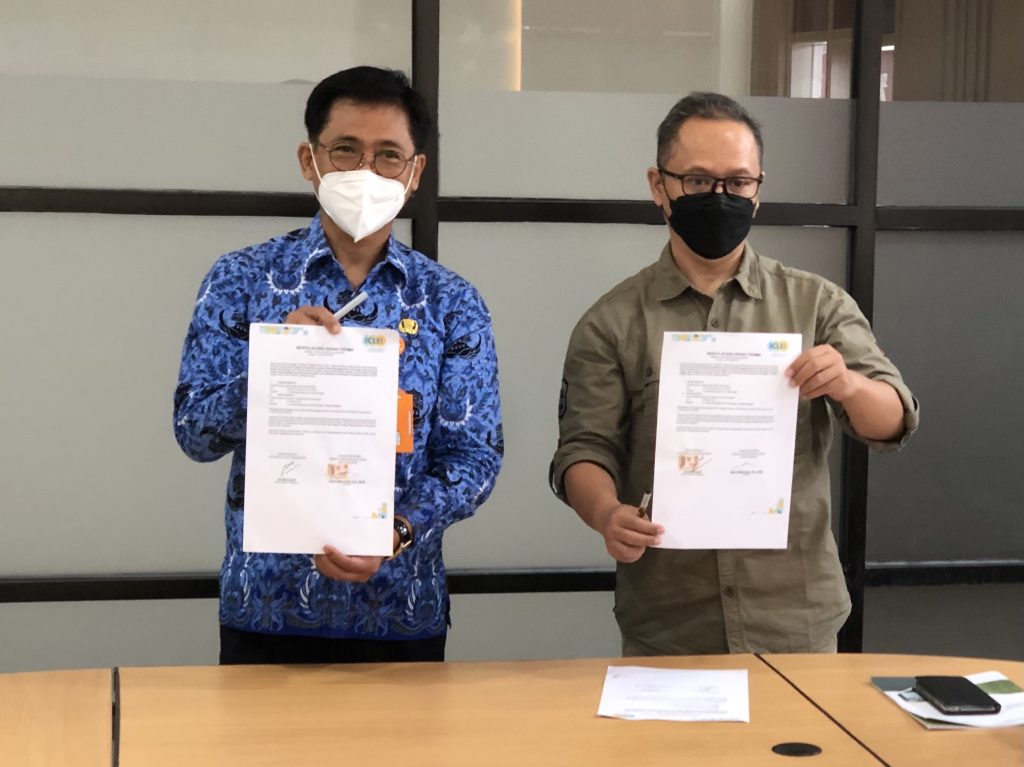

Mr. Ari Mochamad, Country Manager of ICLEI Indonesia handed over the pilot project to the Environment Agency of Bogor City last 18 October 2021.

He said “Waste will continue to exist – and continue to have an impact on the environment and on society. But through collective actions, we can manage to contribute to greenhouse gas emissions reduction from the waste sector as well as support the sustainable development goals of Bogor City, in particular No. 11 (sustainable cities and communities), No. 12 (responsible consumption and production), No. 13 (climate action), and lastly No. 17 (partnership to achieve a goal). Moreover, the product of hydro-pyrolysis, especially solid-liquid fertilizers and liquid oil, adds co-benefits in terms of promoting a circular economy.

Mr. Mochamad also hoped that the Bogor City Government can ensure the sustainability of the pilot project and that the effort can be replicated by other demonstration sites in the future.

During his acceptance of the project, Mr. Denni Wismanto, Head of the Environment Agency stated that “We are really thankful to ICLEI Indonesia Office for choosing Bogor City for this pilot project. We will ensure the sustainability of the facility and hope we can replicate it to 26 temporary collection points within Bogor City administrative areas. We always encourage the community to participate in the terms of waste segregation from their house. Lastly, we hope that the economic value of by-products can be commercialized to give an additional source of revenue for the city”.

The successful implementation of this pilot project supports Bogor’s vision of “Making Bogor a Family Friendly City” by creating a healthy, smart, and prosperous community.

Photo 2: Series of activities: [A] Socialization to the beneficiary community. [B] & [C]. Demonstration site visit by ICLEI Indonesia Office and Environment Agency of Bogor City. [D]. Operator training by the contracted service provider.

Photo 1: The pilot project site is located at 3-R Temporary Collection Point (locally named TPS-3R) Cipaku, East Bogor, Bogor City. [A]. Entrance view of TPS-3R surrounded by small farming areas and a fish pond; [B]. Waste sorting area; [C]. Biogas reactor area; and [D]. Compost storage

Photo 3: ICLEI Indonesia Office officially handed over the facility by signing the facility handover letter (locally named Berita Acara Serah Terima) last 18 October 2021 alongside the Environment Agency of Bogor City to ensure the sustainability of the pilot project.

Photo 4: Hydro-pyrolysis technology: [A]. Without casing and [B]. With casing

Learn more about the Community-Scale Solid Waste Management using Hydro-pyrolysis Technology Pilot Project demonstration implemented in TPS-3R Cipaku, East Bogor, Bogor City below: